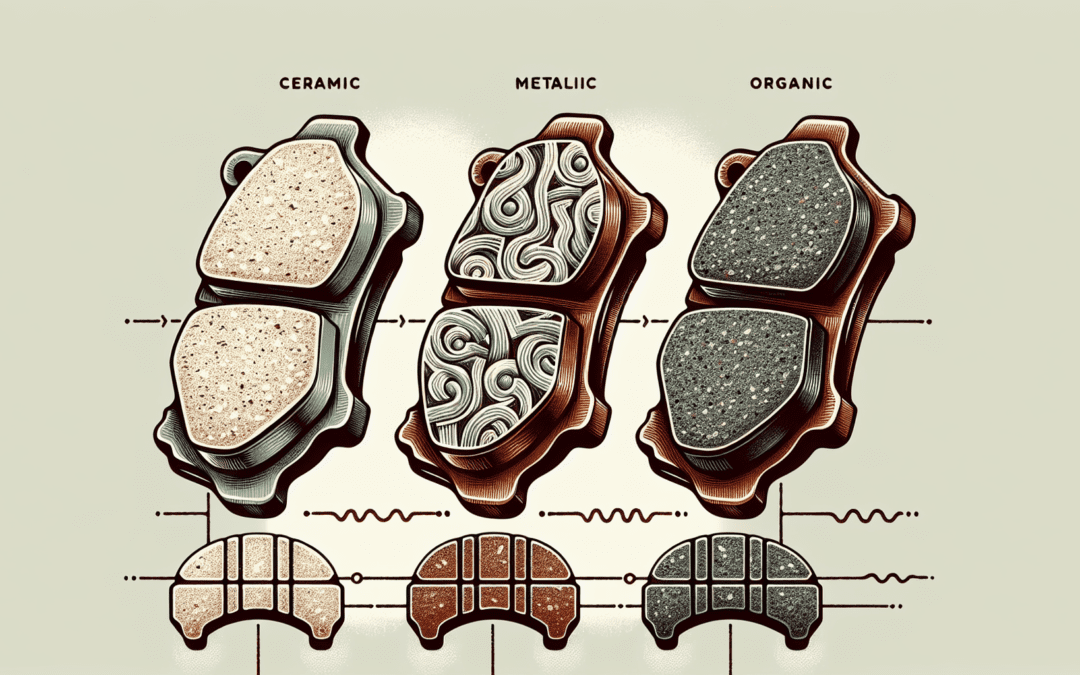

1. Ceramic Brake Pads

- Composition: Ceramic brake pads are made from a combination of ceramic fibers, nonferrous filler materials, and a small amount of metal.

- Advantages:

- Quiet Operation: Ceramic pads are known for their smooth and quiet braking, reducing noise considerably compared to semi-metallic options.

- Low Dust Production: These pads generate less dust, which helps keep wheels cleaner over time.

- Long Lifespan: Ceramic pads generally last longer than organic pads and offer excellent durability. They are particularly well-suited for everyday driving and long-distance travel.

- Performance: They offer great braking performance with a balanced response in both light and moderate driving conditions. They also perform well in cold weather, where other materials might struggle.

- Disadvantages:

- Price: Ceramic pads tend to be more expensive than organic and semi-metallic pads, which can make them less budget-friendly.

- High-Temperature Performance: While they handle moderate heat well, they can suffer from brake fade in extreme high-performance situations (e.g., heavy racing or downhill mountain driving) when compared to semi-metallic pads.

- Rotor Wear: While less abrasive than semi-metallic pads, they can still cause some rotor wear over time, but generally not as much as semi-metallics.

2. Semi-Metallic Brake Pads

- Composition: These pads are made from a blend of metals, such as steel, copper, and iron, mixed with organic materials like graphite and resins.

- Advantages:

- Durability: Semi-metallic pads are extremely durable and last longer than organic brake pads, especially under heavy braking conditions.

- Heat Dissipation: The metal content helps them withstand higher temperatures, making them ideal for performance vehicles or those that frequently experience heavy braking (e.g., trucks or mountain driving).

- Better Performance: They provide consistent and reliable braking performance in a wide range of conditions, particularly at high speeds or with more aggressive driving styles.

- Disadvantages:

- Noise: Semi-metallic pads are typically noisier than organic or ceramic pads due to their metal content, producing a higher-pitched squeal or grinding noise.

- Dust Production: These pads tend to produce more brake dust, which can accumulate on wheels, requiring more frequent cleaning.

- Rotor Wear: The metal particles in the pads can be rough on brake rotors, leading to quicker rotor wear compared to organic options.

3. Organic Brake Pads

- Composition: Organic brake pads, often referred to as non-asbestos organic (NAO) pads, are made from a blend of materials such as rubber, glass, resin, and carbon. They may also contain small amounts of friction modifiers to improve their performance.

- Advantages:

- Quiet Operation: Organic pads are typically the quietest type of brake pads. They produce very little noise compared to semi-metallic or ceramic options.

- Gentle on Rotors: These pads are softer and gentler on brake rotors, leading to less wear on the rotor surfaces.

- Affordable: Organic pads are usually the least expensive option, making them a great choice for budget-conscious drivers or vehicles that don’t require heavy-duty braking performance.

- Low Dust Production: Organic pads tend to produce minimal brake dust, which helps in keeping wheels cleaner.

- Disadvantages:

- Lower Durability: Organic pads wear out more quickly than semi-metallic or ceramic pads, especially in high-stress braking situations (like towing or performance driving).

- Less Effective at High Temperatures: Organic brake pads are more prone to brake fade (loss of braking power) when subjected to high heat, making them unsuitable for heavy-duty use.

- Less Braking Performance: These pads may not provide the best stopping power under demanding driving conditions or high-speed applications.